2/26/2024

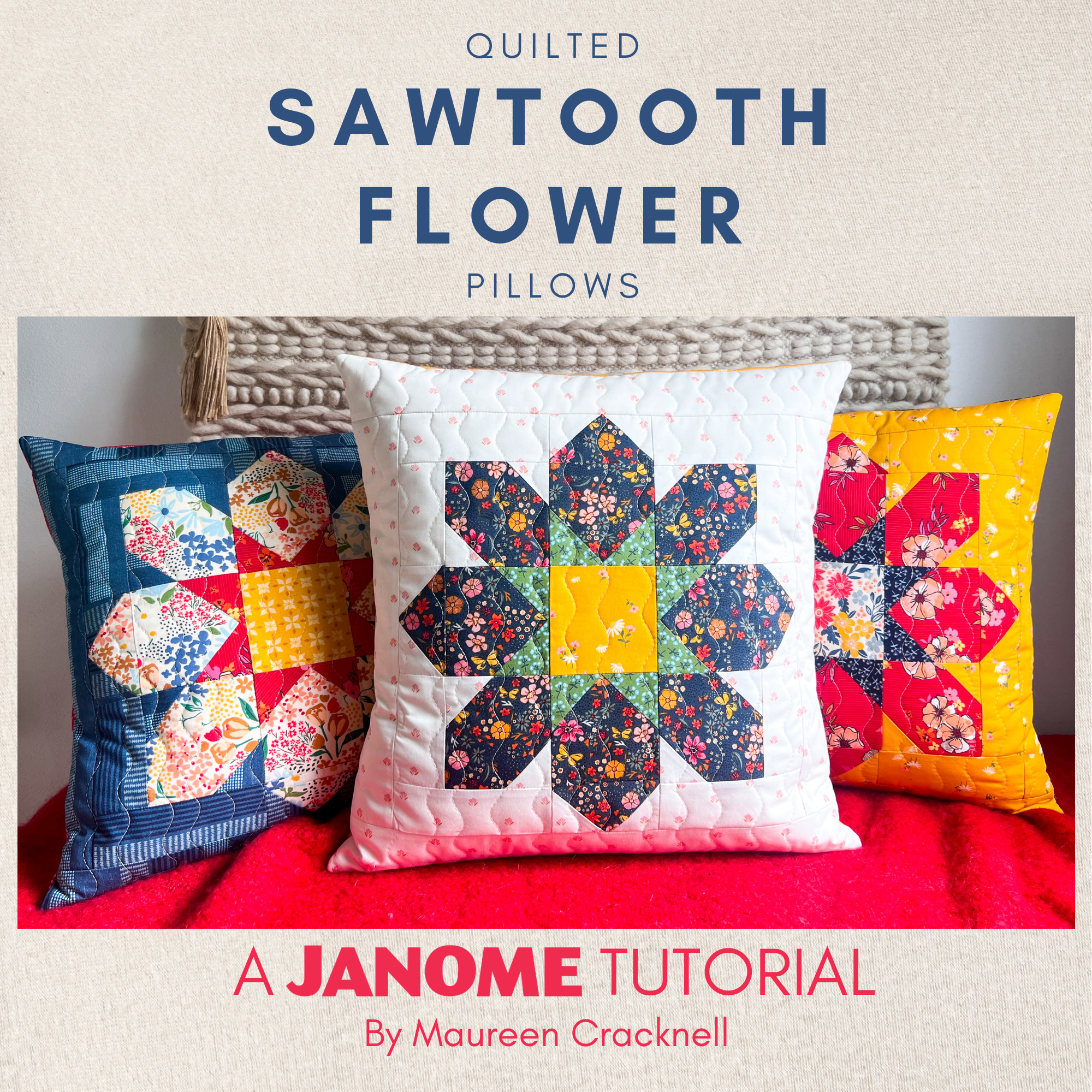

Inspired by my new floral fabric collection The Flower Fields, made using Janome's amazing Continental M17, today's tutorial is for these beautiful and fun Quilted Sawtooth Flower Pillows! The center of this pillow design is a standard 12.5 (unfinished) flower quilt block pattern that can be made over and over to make a quilt, that I finished into a 16" cozy cushion made easy using the CM17's large sewing area, built-in stitches, and incredible speed! Let's get started!